TECHNOLOGIES

How it works

Our structures are designed with FIXED CONNECTIONS.

These connections are VERY STIFF. Thanks to that, the whole structure is well BRACED against lateral forces (wind, earthquake, etc), and RESILIENT against accidental situations (fire, impact, blast, foundation settlement, etc).

Fixed connections are obtained by combining the 3 basic precast components (SLABS, BEAMS, COLUMNS) with some steel and concrete placed at the job (topping).

Learn more about our 3 basic components:

- GROOVED HOLLOWCORE

- BEAMS (several cross-sections)

- COLUMNS

BEFORE & AFTER

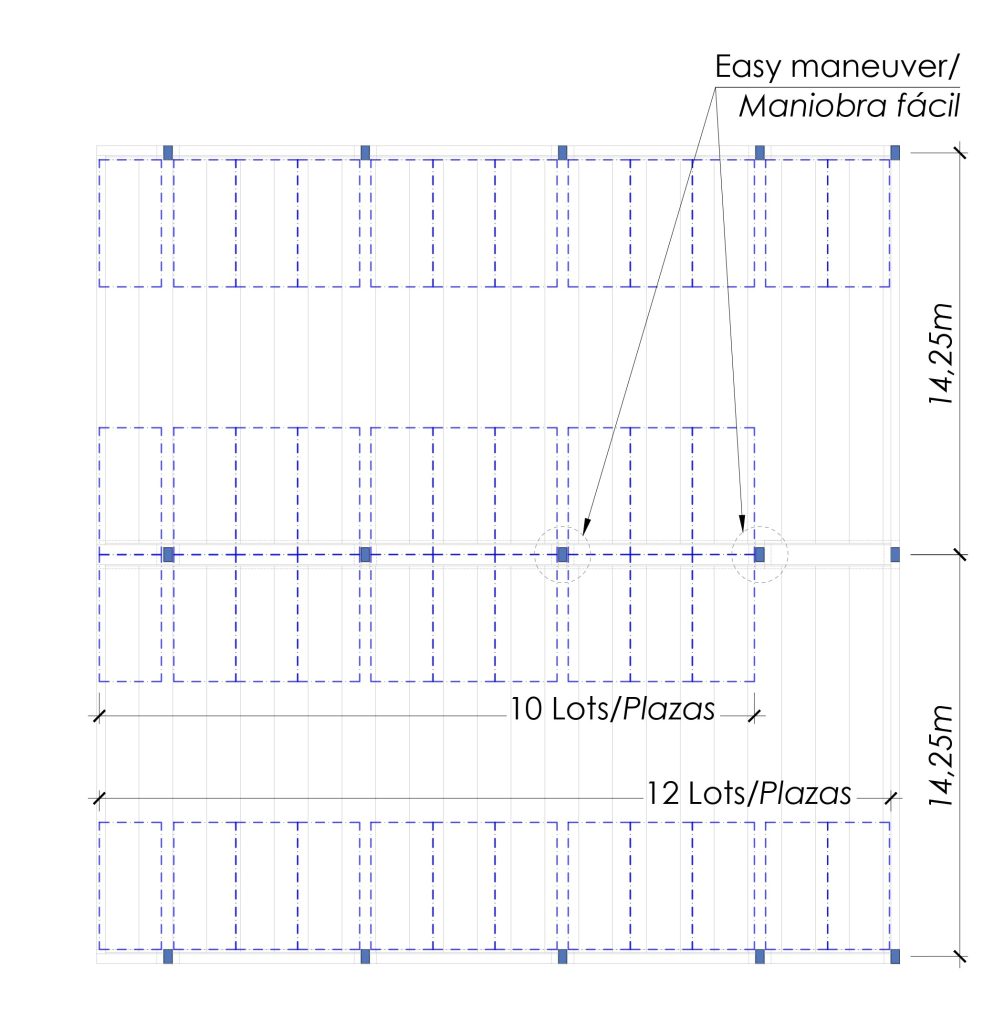

Using Elastic Potential technologies will provide your buildings with wider open spaces, by reducing the number of columns.

FOR DEVELOPERS

We care for rapid construction to deliver valuable properties.

Developers we have worked for

FOR ARCHITECTS

Our designs care about Architecture and environment.

Architects we have worked with

FOR CONTRACTORS

Easy assembly to deliver fast and high-quality industrialized construction buildings.

Contractors WE have worked with

Select your type

Pick the building type you are thinking of, and find out the precast solution we can offer.

Next are some typical building structures, solved with some of the basic structural components that we include in our designs.

Check out also how your building may change by comparing the cast in the job solution to the precast solution.